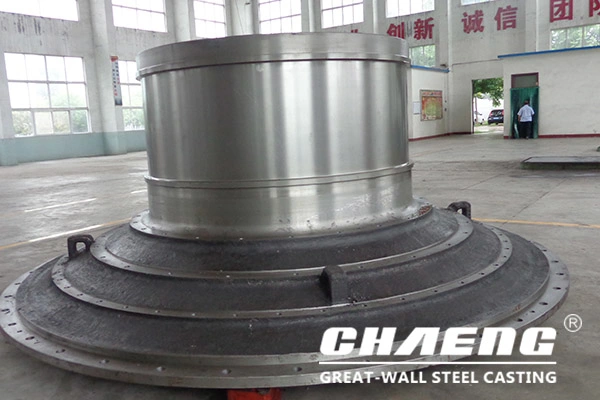

Cement Ball Mill Spare Part Steel End Cover

Introduction Ball mill end cover (ball mill head) is one of the key components of the ball mill, located at both ends of

Description

Basic Info.

| Model NO. | Ball Mill End Cover |

| Specification | steel casting |

| Trademark | CHAENG |

| Origin | Xinxiang City, Henan Province, China |

| Production Capacity | 5000 PCS / Year |

Product Description

IntroductionBall mill end cover (ball mill head) is one of the key components of the ball mill, located at both ends of the ball mill cylinder and is supported on the bearing, mainly used to support the material, the cylinder and the medium. CHAENG can manufacture ball mill end cover (ball mill head) according to users' drawings.

Weight 1-150Tons

Material ZG230-450

Application Building material industry

Customizable Yes, based on user's drawings

Processing advantages

1. High-quality raw materials, mature technology

Use high-quality raw materials and mature technology to guarantee the quality. CHAENG has a wealth of experience in manufacturing ball mill, in the production process, we continue to adopt new technologies and new process to enhance its wear resistance and pressure performance. Our advanced level-2 flaw detection equipment can detect the interior of the end cover accurately to assure the quality.

2. Components are sealed well, no leakage problem

CHAENG feed cover can be produced for a specific device, making adjustments to a certain degree to make end cove joint better with feed components without gaps, to prevent material leakage problem.

3. Stable operation, long service life

CHAENG ball mill end cover adopts high-strength steel, and its structure is optimized by professional engineers according to the operation characteristics of ball mill, to greatly ensure the long-term operation stability and prolong the long service life.

Process

| The first step: Simulation and modeling Before casting, numerically simulate the casting process by CAE software to analyze the molding process, predict and optimize quality of ball mill end cover. The second step: pouring and heat treatment Sample the hot metal and perform the spectral analysis. After qualification, the pouring shall be carried out according to the principle of "low temperature and quick casting", and the pouring time and temperature shall be recorded. The third step: Flaw detection, finishing Finally, cut the pouring riser and burr etc. CHAENG has professional mechanical polishing teams and large-scale blasting apparatus, which can effectively improve the appearance quality of ball mill cover, to meet customer's requirements on surface finish. Moreover CHAENG take use of advanced detection equipment for non-destructive testing to ensure the internal quality. |

Case

CHAENG ball mills are exported to more than 50 countries and regions, and the matched trunnion and end cover are all independently manufactured. CHAENG also can produce the ball mill trunnion and end cover for other factories according to customers' drawings.

Chaeng Service

1. Cost-effective

CHAENG has the advanced casting equipment, strictly follows the national lever-2 detection standards, and executes 360° all-round nondestructive testing system, to ensure the reliable quality and long service life of steel castings. CHAENG is hailed as "high cost-effective steel castings manufacturer".

2. Fast delivery

CHAENG has strong technical teams, detailed production scheduling, wide range of raw materials purchase channels, and perfect logistics delivery system, making efforts to achieve as fast delivery period as required.

3. "Three-heart" service

The 24h fast response and the customer services in all 365 days rest your heart when you make choice, ease your heart when you use the products, satisfy your heart when you enjoy the services.

Our Contact

Send now