Multi

Multi-uses 5-150 m3/h Rock Stone Glass Crusher Stone Crusher Hammer 1.Product Description of Stone Crusher Hammer Stone

Description

Basic Info.

| Model NO. | pc 400x300 -pc 1600x1600 |

| Inlet Size | 0-300 mm |

| Condition | New |

| Factory Visit | Welcome Warmly |

| Quality | High Level |

| Capacity | 5-150 M3/H |

| Color | Customzing |

| Factory | Henan Hongke Heavy Machinery |

| Product Name | Stone Crusher Hammer |

| Transport Package | Container |

| Specification | PC series |

| Trademark | Hongke |

| Origin | China |

| HS Code | 8451290000 |

| Production Capacity | 500 Units Per Month |

Product Description

Multi-uses 5-150 m3/h Rock Stone Glass Crusher Stone Crusher Hammer

| Product Name | Stone crusher hammer |

| Suitable for | Crushing Ores and Stone |

| Color | Customizable |

Stone crusher hammer is a machine used to shred or crush materials into smaller pieces.

The basic design of this type machines involves a rotating shaft which free-swinging hammers are attached.

This assembly is enclosed by a drum which carries the material to be pulverized. A hopper is used to feed the source material into the drum. The hammers gradually crush material until it is small enough to pass through a screen with openings inaccordance with the desired particle size.

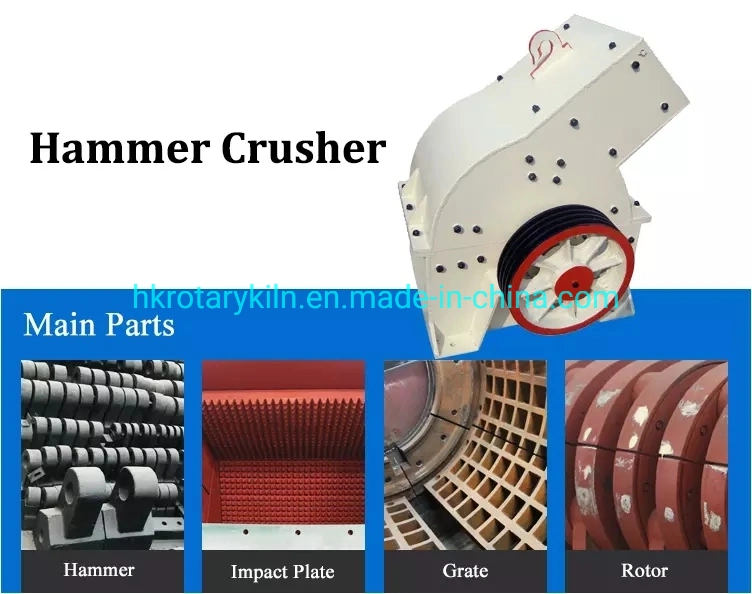

2. Working Principle of Stone Crusher Hammer 1. Stone Crusher Hammer mainly consists of frame, rotor, support iron and grate bars.

2.The frame is divided into two parts: Upper part and lower part which are welded by steel plates after being cut.

3.Liners made of high manganese steels within the frame can be replaced after being worn out.

4.The rotors consist of the turn plate, pin shafts, and hammers which are grouped regularly in the main shaft.

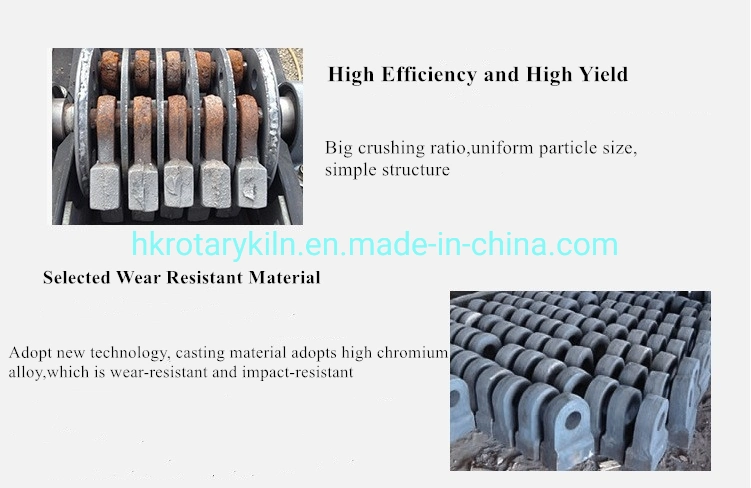

5.The motor drives the rotors to rotate quickly in the crushing cavity, and hammers spread outward as a result of centrifugal

force from the rotation of the rotors.

6.Large materials entering the crusher through the feed inlet are stricken, impacted, cut and ground by the high-speed hammers to small size.

7.Qualified materials crushed will be screened out and exit from the gap of the grate bars while the unqualified will be left in

the crushing.

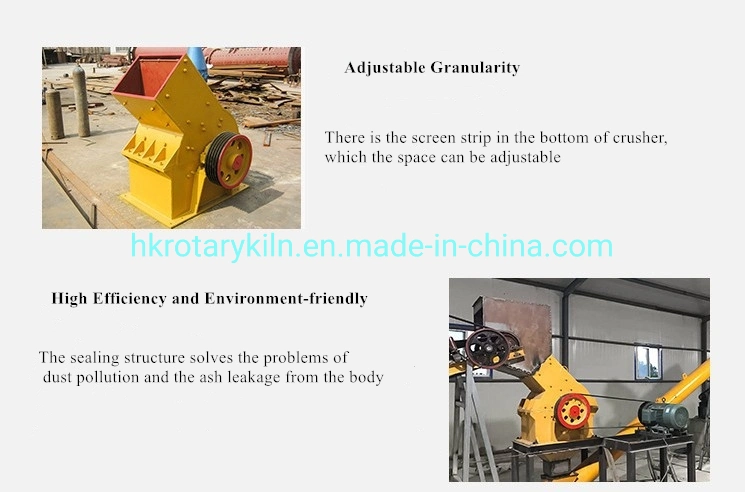

8.The size of the final product can be adjusted by changing the grate bars.

9.The gap between the rotors and the grate bars can also be adjusted according to different requirement.

3.Factory Pictures of Stone Crusher Hammer

4.Size Information of Stone Crusher Hammer

5. Working Sites of Stone Crusher Hammer

6.Company Introduction

Henan Hongke Heavy Machinery Co., Ltd. is located in Henan Province which is the cultural base of the central area of China. We are a mining machinery manufacturing enterprise that integrates scientific research, production and marketing.We are a high-tech enterprise that specializes in the research and production of rotary kilns, dryers, crushers and so on, such as new type of lime rotary kiln, ceramsite kiln, zinc oxide rotary kiln, sludge rotary kiln, chemical rotary kiln, metallurgical rotary kiln, Raymond mill, ultra-fine mill, large and medium dryer, ball mill, sand mill,stone production line, mineral processing equipment and so on.From the design, production, installation and debugging, we provide you the entire tracking service.We adhere to the aim of high quality to survive, good credibility to make development, and sincerely look forward to cooperating with you!

7.FAQ

1. What is the minium order quantity?One set.2.How long is the warranty period?One year. Wearing parts are excluded.3. What is the after-service of your company?We can provide the customers foudation drawing, installation service, work training as well as other service according to thecustomer's requirements.4.How long is the delivery time?About 15 days after we receive the payment.5. What are the payment terms?T/T, L/C are the best, it can be adjustable according to different situations.--------------------------------------------------------------------------------------

Kindly Note:

1. Please pay attention to the capacity. It's what you must take into consideration in choosing a suitable machine.2. Please Inform us the follow figures:1). feeding material2). Feeding material MAX. Size (mm)3). Final mesh size (mm)4). Capacity (t/h)

Upon we got your message we shall give you our favorable offer in short time.

Prev: Quarry and Mining Crusher Spare Parts Jaw Plate Mantle Concave Bowl Liner

Next: Mining Equipment Spare Parts HP Cone Crusher Liner Filler Backing Compound

Our Contact

Send now