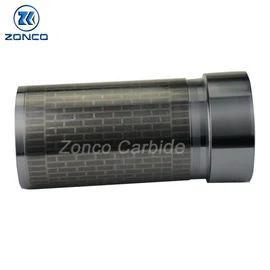

Tungsten Carbide Tc Radial Bearing Chemical Resistance for Downhole Motor

Description

Basic Info.

| Model NO. | Zonco-10223 |

| Working Temperature | in Excess of 2000° F (1093° C) |

| Surface Treatment | Carbide Tile Insert |

| Manufacturing Process | Pta Processing |

| Transport Package | Wood Package / Customize Packing |

| Specification | Customized |

| Trademark | Zonco |

| Origin | China |

| HS Code | 84833000 |

| Production Capacity | 500PCS Per Month |

Product Description

Tungsten Carbide TC Radial Bearing Chemical Resistance for Downhole Motor

1. Advanced technology (with our advanced sintering technology the cemented carbide layer is closely combined with the substrate extremely resistant to chipping,cracking and flaking)

2. High wear-resistance (Tungsten carbide coverage is ≥55%,it's highly wear-resistant,working life over 300 hours)

3. Good wirgin material(Virgin material largely determines the quality of product.We use 100% good virgin material to make sure high quality)

4. Stable quality(No matter samples or big order,we make sure each bearing meet our high standard,stable quality gives you better usage experience)

Advantages:

1. Increased Bearing LifeOur exclusive cladding sustains tight tolerances and remains durable, even under extreme heat and stress.2. Reduced Operational Costs3. Improved Mud Motor PerformanceOperators can push motors without damaging the bearings, permitting sharper turns, faster penetration and less drilling time.4. Enhanced Drilling AccuracyReduced bearing wear means that design tolerances are maintained downhole, resulting in improved mud motor control and greater drilling accuracy.

5. OEM customized sizes available 6. Factory's offer

Features:

1. Stable chemical properties 2. HIP sintering, good compactness3. Excellent performance and good wear / corrosion resistance 4. Blanks, high machining accuracy / precision

Common Alloy Grades, Ghysical Mechanical Properties And Recommended Application | |||||||

| Grade | WC% | Co/Ni % | Physical and mechanical properties | Grain size (μm) | Recommended application | ||

| Density (g/cm3) | TRS (N/mm2) | Hardness (HRA) | |||||

| ZG06 | 94 | 6 | 14.8-15.1 | 2500 | 90.0 | 1.2 | Good abrasion resistance, good compression resistance, suitable for wear-resistant parts that resist abrasion and high pressure. |

| ZG06X | 94 | 6 | 14.8-15.1 | 2400 | 91.5 | 1.0 | Superio wear resistance,good comprehensive properties,suitable for making non-standard structure components with higher wear resistance. |

| ZG06A | 94 | 6 | 14.8-15.1 | 2150 | 92.5 | 0.6-0.8 | |

| ZG08 | 92 | 8 | 14.6-14.9 | 2700 | 89.0 | 1.2-1.6 | Good general performance, used for general wear parts, molds, general tools, etc. |

| ZG11 | 89 | 11 | 14.3-14.7 | 2800 | 88.5 | 1.2-1.6 | Anti-wear, anti-erosion, good comprehensive mechanical strength, suitable for wear-resistant parts in the petroleum, chemical and mechanical industries. |

| ZG12X | 88 | 12 | 14.2-14.5 | 3000 | 89.5 | 1.0-1.2 | Anti-erosion, good comprehensive mechanical strength, suitable for impact-resistant wear-resistant parts, molds, and roller rings. |

| ZG15 | 85 | 15 | 13.8-14.2 | 3000 | 86.5 | 1.2-1.6 | |

| ZG15X | 85 | 15 | 13.8-14.2 | 4500 | 89.0 | 0.7 | Excellent wear resistance and toughness,it is suitable for making integral stamping dies, anti-vibration toolholders, etc. |

| ZG20 | 80 | 20 | 13.4-13.8 | 3100 | 85.0 | 1.0 | Excellent wear resistance and toughness |

| ZN06 | 94 | 6 | 14.5-14.9 | 2000 | 90.0 | 1.2 | Non-magnetic alloy, suitable for sealing ring, non-magnetic wear-resistant parts and corrosion-resistant parts. |

| ZN09 | 91 | 9 | 14.3-14.6 | 2300 | 89.0 | 1.2-1.6 | |

| ZN11 | 89 | 11 | 14.0-14.3 | 2600 | 88.0 | 1.2 | |

Our Contact