Vertical Mill Grinding Roller Spare Parts

Technical Documents and Lists of HRM Veritical roller mill 1. Structure and Working Principle of Model HRM Vertical Mill

Description

Basic Info.

| Model NO. | HRM53.4 HRM17.2 HRM36.3 |

| Transport Package | Bulk |

| Specification | HRM3400 |

| Trademark | HRM |

| Origin | Hefei |

| HS Code | 8474900000 |

| Production Capacity | 200 |

Product Description

Technical Documents and Lists of HRM Veritical roller mill

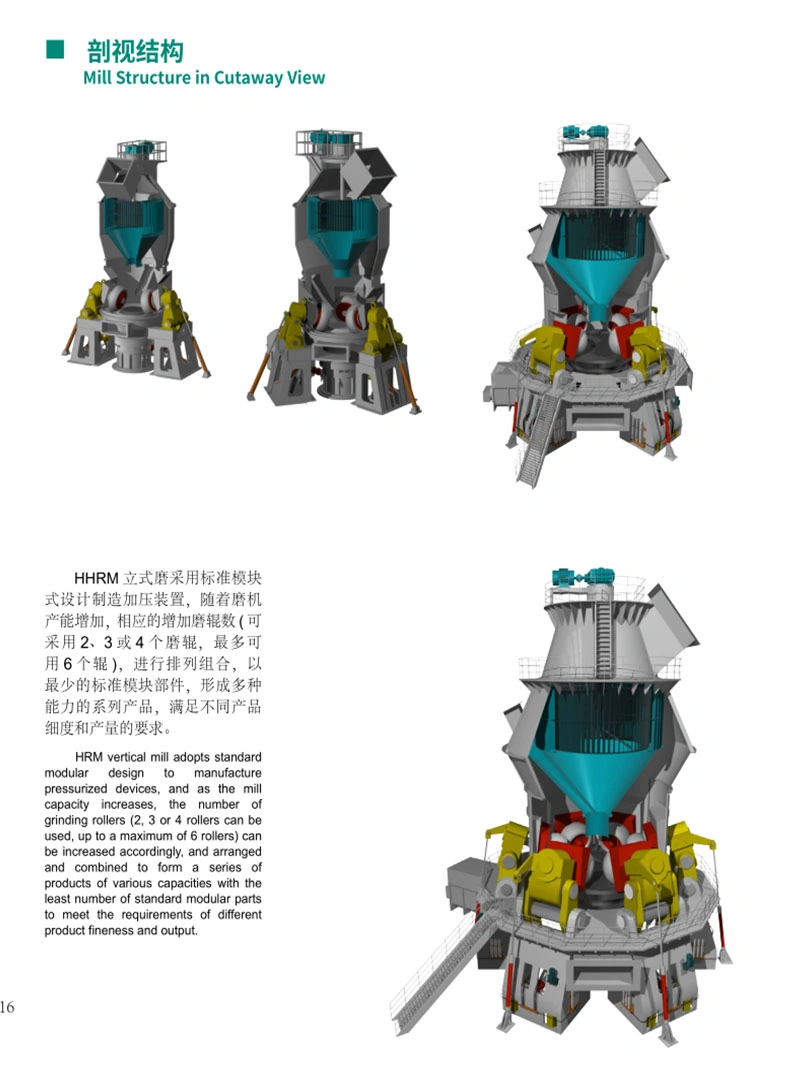

1. Structure and Working Principle of Model HRM Vertical MillHefei Cement Research and Design Institute began to make research on the vertical mill at the beginning of 1980s and has designed a new type energy-saving grinding equipment ---HRM veridical mill on the basis of widely collecting the data of various vertical mills both at home and abroad and absorbing the international advanced technology and combining them with the characteristic of the cement industry of our country.

It has following advantages such as turning the grinding roller out of the mill for easy maintenance like LM vertical mill and turning over the roller sleeve for use to prolong the service life like MPS vertical mill. (As shown in the following diagram)

Model HRM vertical mill is the new type energy-saving grinding equipment and its working principles are:

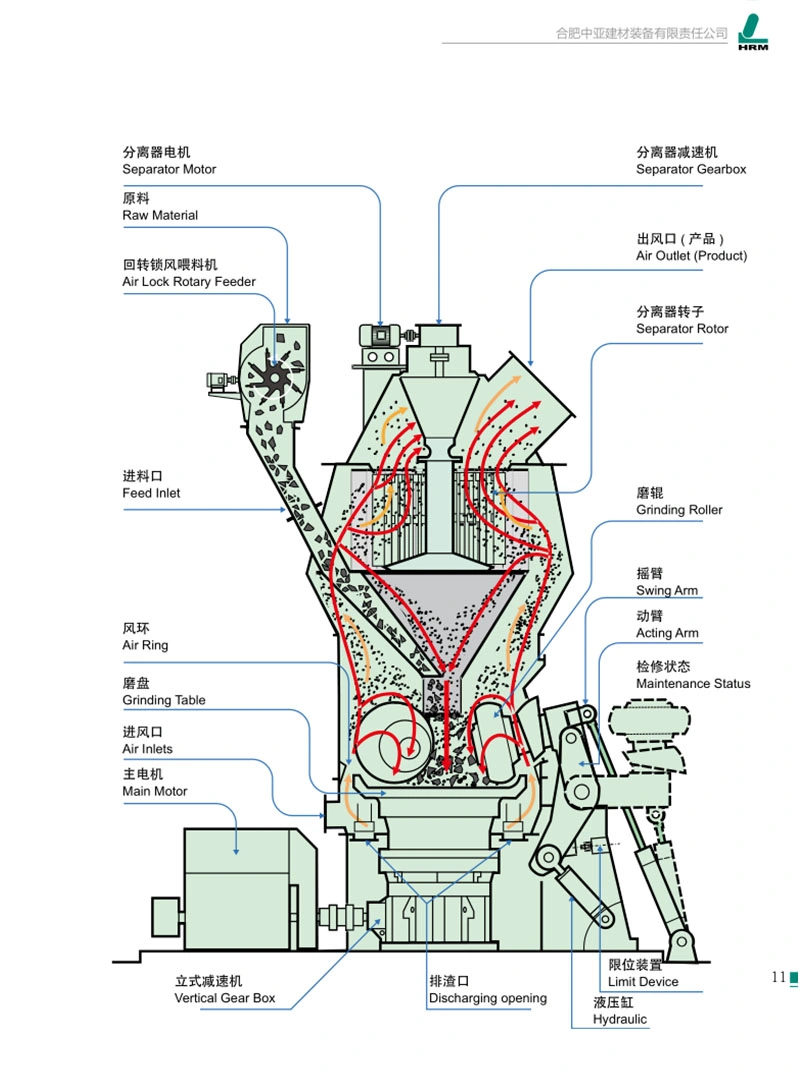

The motor drives the speed reducer to put the grinding disc in motion. The material needing grinding is sent into the center of the grinding disc through air-locked feeding equipment, moves to the perimeter of the grinding disc under the action of the centrifugal force and enters into the grinding roll table. The grinding roller applies the grinding force to the material inside the roll table by the action of hydraulic device and driving arm so that the material is pulverized after extrusion and cutting. Meanwhile, the hot blast air up-gushes evenly at high speed from the vane around grinding disc. The material after pulverization blows up by the high speed air flow at the vane , blowing the coarse material back to the grinding disc for regrinding on the one hand and drying the suspended material on the other hand, while the fine powder is brought into separator by hot blast air for classification. The qualified fine powder goes out of the mill along with the air flow and becomes the product after being collected by the dust removal equipment. The substandard will fall down again to the grinding disc by the action of the blade of separator and be reground together with the newly fed material. A cycle begins to complete the whole process of grinding operation.

2. Structural Features and Technical Superiorities of Main Parts of Model HRM Vertical Mill

2.1. Driving device:

The driving device of HRM vertical mill consists of main motor, coupling and speed reducer and is mounted at the lower part of the mill. It not only drives the rotation of grinding disc, but also withstands the weight of grinding disc, material, grinding roller and grinding pressure applied by the pressure device, so it is one of the most important parts of the vertical coal mill. The speed reducer of vertical mill adopts the combined transmission mode of bevel gear wheel and planetary gear. A couple of right-angle driven bevel gear wheel and a set of input shaft are for vertical ascending planetary drive and both are connected through pairs of gear coupling. The sun wheel is supported on the trust piece with ball head and the axial bearing of planet carrier is supported by a set of round thrust bearing with tiltable bush. These two free degrees make the annular gear and three planet wheels evenly stressed. The annular gear is rigidly fixed on the box and cylindraceous box and cylindraceous box provides the axial thrust bearing with ideal supporting form. Besides, the inner and outer walls of the cylindraceous box are equipped with symmetrical reinforcing ribs so that the box has very good rigidity. The tapered gear uses helical teeth and sun wheel and planetary gear are of involute straight teeth, which are all made of high strength alloy steel. The teeth of gears have undergone carburized grinding and have higher precision. All the pedestal bearings of the speed reducer adopt rolling bearing. The axial trust bearing is of trust bearing with tiltable bush and can withstand the vertical radial force of vertical mill. The bearing bush is immersed in the oil pool during working and constantly provides fresh lubrication oil through ring nozzle. The oil pool should always be kept at a certain level. The lubrication system adopts independent oil station and is furnished with automatic protection systems for oil pressure and temperature so that the whole set of equipment can work safely and reliably. The speed reducer of this type has the advantages of small size, light weight, great speed reducing ratio and high driving efficiency etc.

2.2. Grinding device

Grinding disc and roller are important grinding parts and their shape must be so designed as to form a stable material bed with even thickness, therefore, the rational grinding disc shape matched with appropriate grinding rollers plays a very important role in stabilizing the material bed, raising grinding efficiency and reducing the consumption of grinding body. Through a large numbers of investigation and comparison, we use arc-type liner and tyre-type roller sleeve, which is of symmetrical structure and can be turned over for use after wearing to certain extent, thus prolonging the service life.

2.3. Pressure device

Model HRM vertical coal mill applies and controls its acting force for material by using hydraulic automatic or manual control system and the pressure can be automatically adjusted according to the variation of grindability of the material, so the mill can often keep working under the most economic condition. So, it can not only reduces the consumption of idle work, but also prolong the service life of roller sleeve and liner .Meanwhile, the pressure application of hydraulic cylinder is more flexible and pressure can be automatically adjusted due to the pressure maintaining and overload cushion of accumulator. When meeting large and hard foreign matters, the grinding roller can jump up, avoiding the damage of grinding parts and driving device due to excessive loads.

2.4. Stop block

The stop block of model HRM vertical coal mill can avoid the vibration and jump stop of the mill in case of the damage to material beds and can ensure continuous and stable operation of the mill. The clearance between grinding roller and grinding disc can be adjusted so that it not only can keep stable material layer thickness, raise the grinding efficiency, but also ensure that there is no direct contact between grinding roller and disc and protect speed reducer.

2.5. Separation device

The HRM vertical mill is so designed that the separator is of mechanical drive and rotation speed adjustable. The separator, through high speed rotation of tapered rotor, bumping of blade with coarse granules, provides the material with larger peripheral speed and produces greater centrifugal force for separation. The fine granules can go out of the mill through the gap between blades of separator and collected by dust collector. The classification efficiency of the separator is high and has great room for adjustment.

2.6. Grinding rollers

HRM vertical mill: The grinding roller device adopts a pair of self-aligning roller bearing and the service life of bearing etc has been calculated during design. The seal cavity of bearing is located at the outside of the bearing housing and does not contact with the dusty air, so the simple packing seal can reach very good sealing effect. The air fan does not need to be sealed and the bearing of grinding roller is lubricated with thin oil, which greatly improve the lubrication and cooling effect and raise the service life of bearing by 2.5 times.

2.7. Others

(a)Model HRM vertical mill has no horizontal surface inside , so it will not cause the sediment of powder. Besides it has a bleed hole at the lower casing, the foreign material difficult to be ground can be discharged out of the mill at any time and the residues will also be drained empty after shutdown.

(b)The grinding roller can be turned out of the mill by means of hydraulic roller tilting device for repairing and changing the easily wearing parts, thus shortening the stopping time and raising the operating rate.

(c)The grinding roller and casing adopt the arc-type plate sealing structure and has the features of good sealing effect and durable service etc compared with the traditional structure.

2.8. Starting sequence of the mill

Start up the oil pump of the lubrication oil station( 5-10 minutes when the oil pressure is at 0.25Mpa) )→ turn the separator to the working speed → start up the oil pump of hydraulic station→ open change valve→ raise the grinding roller (about 100 mm in height ) →start up main motor →put the material → lower the roller .

Our Contact

Send now